uv coating spray line for Vacuum Metalization Coating

Our uv coating spray is compatible with both plastic and metal products painting treatment such as plastic frames, food cans, furnitures, art works and so on. It's especially useful in vacuum metalizing coating spray. Once done, the surface will be formed bright thin coating. UV coatings can be formulated up to 100% solids so that they have no volatile component that contributes to pollution. This high solids level also allows for the coating to be applied in very thin films. UV coatings can be formulated to a wide variety of gloss ranges and can be applied via most conventional industrial coating applications as well as by silkscreen.

Specifications

Button control system by PLC

IWATA or Devilbiss spray guns

Long life cycle Pramarc UV lamps

Accurate temperature & energy control

Manual or 100% automatic spraying

Fast curing and drying

We have a team of genius in spray coating industry. They design and produce via leading concepts and technologies. Our uv coating line comes with advanced layout and long life cycle. You will maintain the equipment with the least effort in short time.

Vacuum metalization machine

1) Electrostatic booth, 1 set

l Size: L1500mm*W2000mm*H2000

l Electrostatic dust guns: 4sets

l Blower(fan): 1set

l Rotation device: 1set

l Frequency convert(1 set) DVS-ZS007G/0.75KW

l Motor(1set):0.55kw

plastic cultery PVD coating equipment silver color UV vacuum metalizing machine

2) Spray booth, 1 set

l Size: L4000mm*W2500mm*H2000mm, 1 set

l Water screen: made of 1.0mm stainless steel

l Water tank plate: 3.0mm iron plate.

l Water pump: used pipeline pump, 2.0kw

l Fan: 6’’centrifugal blower,5.5kw

l Explosion proof fluorescent lamp(1set)

l Rotation device(1set):

l Working principle: painting booth is composed of the water storage tank, paint mist filtration system,

ventilation systems, and control systems. After the first curtain panels recycle paint mist generated and

then filtered by "S"-type water board of ventilation fan, improving purification effect.

plastic cultery PVD coating equipment silver color UV vacuum metalizing machine

3) IR booth, 1 set

l Size: IR oven booth: L20000mm*W1100mm*H750MM 1set

l Tunnel-Type infrared oven: 1set

l Highest temperature:100℃(Automatic constant temperature control system)

l Temperature-controlled: 1 set

l Air circulation system: 1 set

l IR heaters: 12sets*1kw

1) Drying box inside: 0.6mm thick, galvanized sheet (Special Edition)

2) The heat insulating layer: made of asbestos fibers, thickness 50mm

plastic cultery PVD coating equipment silver color UV vacuum metalizing machine

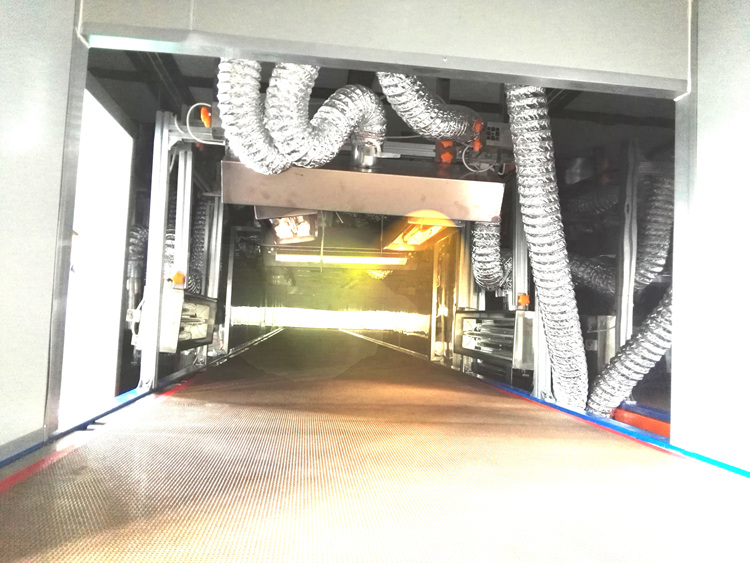

4) UV curing booth, 1 set

l Size: L3000mm*W2000mm*H2000mm, 1 set

l Curing area: UV ultraviolet lamp 5kw (6 sets), independent control, the formation of Omni-directional

radiation exposure, and adjustable, with reflection shade. Bright light, low light device,

cooling the lamp 2 sets from the core fans, with air purification systems, preheating the inside mirror

is made of stainless steel plates, lights inside is mirror stainless steel reflector, lateral plates, double-layer

asbestos insulation;

l Workpiece cooling area, made of galvanized sheet, fan cooling, and filtration devices.

l Characteristics: energy-saving, de-dust, easy to clean, adjust, easy to maintain.

plastic cultery PVD coating equipment silver color UV vacuum metalizing machine

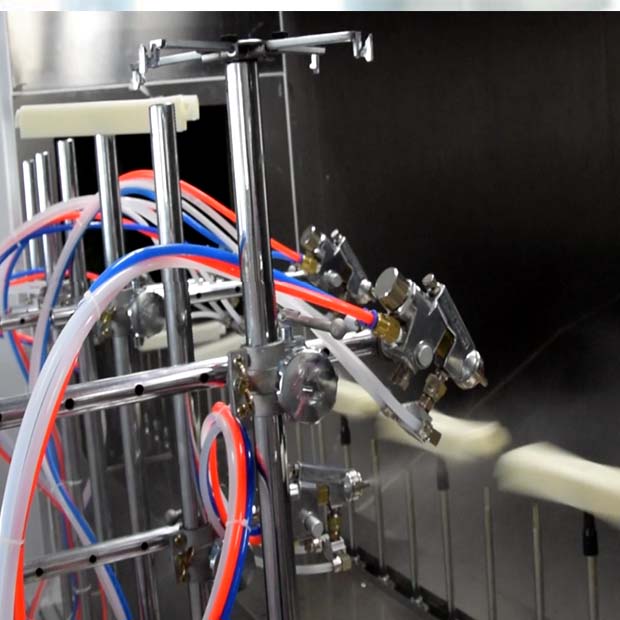

5) Spray gun, 8 sets

l Spray gun(WA101), IWATA made in Japan

l Spray gun stand: 8sets Adjustable angle, distance, position, height

l Corner device:8sets

l Pneumatic pressure regulating device: 1set

l Workpiece rotating device:1set

l Paints supply device: SS304 paint tank 1set

plastic cultery PVD coating equipment silver color UV vacuum metalizing machine

7) Rotation chain system

l Conveyor length: About 50m.

l Rotors: distance between two rotors is 50.8mm. 986pics.

l 50×50 angle, cold rolling plate:2mm

l Speed of the conveyor:1~22m/min(Electronic frequency conversion control)

l Working table: thickness is 1.0 mm, stainless steel and 3.0mm thickness base board

\

\

8) Control system(PLC+HMI)

l Touching screen size: 10.4 inch

l PLC control system: 1set

l Frequency control system : 6sets

l Temperature control device, AC contactor, overload protector

l Fault alert system: 1 set

l Switch and signal lamp: 1 set

Contact: de zhi xie

Phone: +86-138 2651 4079

E-mail: xiedezhi88@gmail.com

Add: Building 37, NO.2 industrial park, shapu wai, songgang town, shenzhen city, guangdong province, China